By DMJ Solutions This program can be used to simulate the s7-200 plc and the TD 200 HMI this is an ideal product to test programs written in microwin if you do not have a plc. Export your program. STEP 7 MicroWIN is a powerful software for Siemens S7-200 series programming. Plcs in this family are commonly used for controlling, monitoring and directing industrial devices at medium levels and since they are one of the inexpensive PCC families, they are widely used in small and medium industries. The S7-200 SMART series is a line of micro-programmable logic controllers (Micro PLCs) that can control a variety of automation applications. Compact design, low cost, and a powerful instruction set make. The first entries in the S7 line were released in 1994, available under three performance classes: S7-200, S7-300 and S7-400. The introduction of SIMATIC S7 saw also the release of a new fieldbus standard.

Product description

The SIMATIC S7-200 Micro PLC is in a class by itself:

Exceptionally compact yet remarkably capable – especially with respect to its real-time performance – it is fast, features great communication options, and comes with easy to operate hardware and software. But there’s more to it than that:

The SIMATIC S7-200 Micro PLC has a consistently modular design – for customized solutions which are not too large for the present but open-ended enough to be expanded anytime in the future. All this makes the SIMATIC S7-200 Micro PLC a highly effective and economical solution for automated control in the compact performance range.

Application area

SIMATIC S7-200

Micro PLC for simple automation tasks

The fields of application of the SIMATIC S7-200 extend from replacement of relays and contactors up to more complex automation tasks in stand-alone mode, in networks, and within distributed configurations. The S7-200 also increasingly provides access to areas in which special electronics was previously developed for economic reasons.

In addition to the comprehensive basic functionality of the five different CPUs, the modular system technology of the SIMATIC S7-200 offers a wide range of scalable and specific expansion modules for an extremely high range of functionalities in accordance with requirements.

The S7-200 has been proven worldwide in applications covering all sectors as a result of its wide range of exceptional features:

CPU 221

Compact CPU for simple automation tasks – The best compact device if you want to change to an effective solution that performs simple automation tasks very economically. Also available with an extended temperature range.

CPU 222

Expandable compact CPU for more complex tasks – The capable, compact package for more complex machines and small system solutions.

CPU 224

CPU for higher communication and computing requirements – The high-performance CPU for complex tasks that require speed and special communication capabilities.

CPU 224 XP

CPU for simple drive tasks – The CPU 224 version for convenient implementation of simple drive tasks – with two interfaces, two analog inputs and one analog output, as well as two 100-kHz pulse outputs and two high-speed 200-kHz counters.

CPU 226

High-performance CPU for larger technical tasks – The versatile high-performance CPU for complex automation tasks with expanded inputs and outputs as well as two RS485 interfaces.

Benefits

SIMATIC S7-200 delivers consistently economical solutions. The entire system family features

Simatic S7 200 Software

- powerful performance,

- optimum modularity and

- open communications.

Weltweit bewährt sich die S7-200 durch ihre Fülle an herausragenden Eigenschaften in Anwendungen über alle Branchen:

- Small and compact – ideal for any applications where space is tight

- Basic and advanced functionality in all CPU models

- Large program and data memory

- Outstanding real-time response – being in total command of the entire process at any time means increased quality, efficiency and safety

- Easy-to-use STEP 7-Micro/WIN engineering software – ideal for both beginners and experts

- Integrated R-S 485-interface or use as system bus

- Extremely fast and precise operational sequence and process control

- Complete control of time-critical processes by time interrupts

Design and functions

Optimal modularity

- 5 distinct CPUs in the performance range with comprehensive basic functionalityand integrated Freeport communications interface

- A wide range of expansion modules for various functions:

– Digital/analog expansions, scalable to specific requirements

– PROFIBUS communication as a slave

– AS-Interface communication as a master

– Exact temperature measurement

– Positioning

– Remote diagnostics

– Ethernet/Internet communications

– SIWAREX MS weighing module - HMI functions

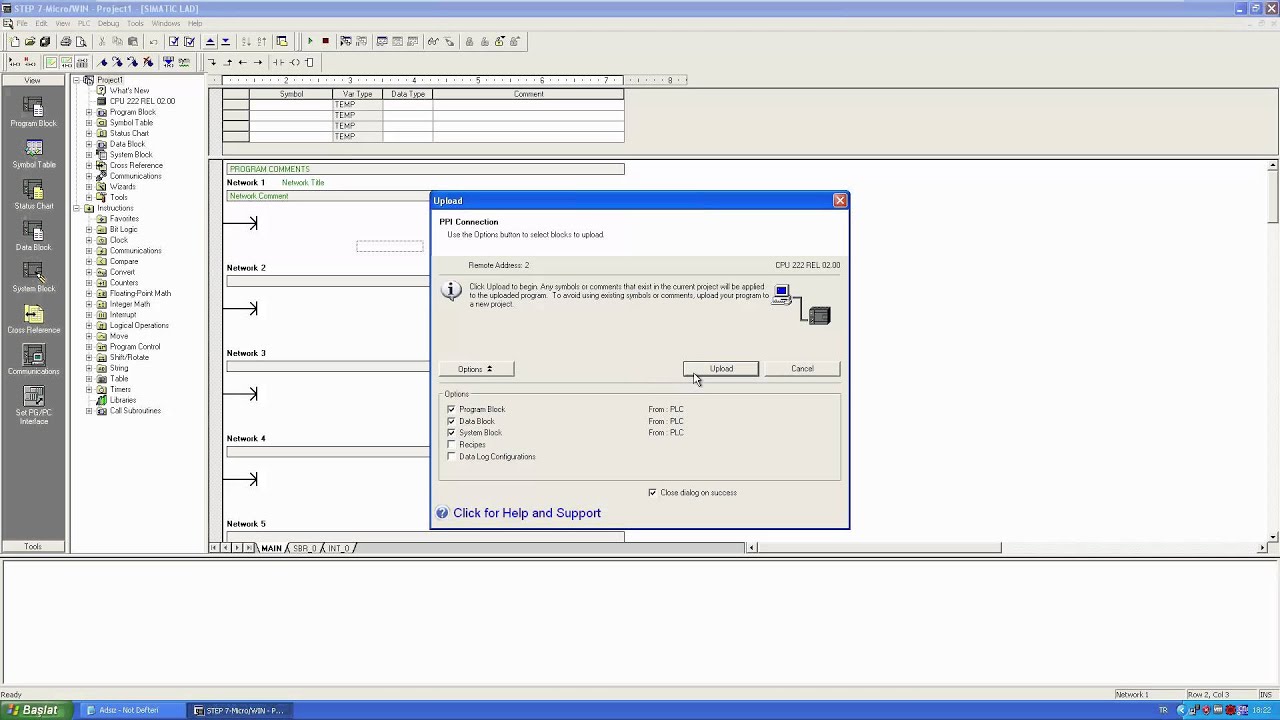

- STEP 7-Micro/WIN software with Micro/WIN add-on instruction library

- Compelling systems engineering – now featuring precise dimensioning andoptimum solutions for a wide range of different requirements for the completeautomation task

Highlights

- Memory card for data logging, recipe management, saving of STEP 7-Micro/WIN project, and storageof documentation in various formats

- PID auto-tune function

- 2 built-in serial ports for extended communication options, e.g. with other manufacturers’ devices(CPU 224 XP, CPU 226)

- CPU 224 XP with built-in analog inputs/output

Real-time response

The advanced technology down to the last detail ensures our CPUs deliver excellent real-time response rates:

- 4 or 6 independent hardware counters, each with 30 kHz, 2 x 200 kHz with a CPU 224 XP, e.g. for precise path monitoring with incremental encoders or for high-speed counting of process events

- 4 independent alarm inputs, input filter time 0.2 ms to program action – for maximum process safety

- Pulse-capturing function for signals > 0.2 ms for fast events from the application

- 2 pulse outputs, each 20 kHz, or 2 x 100 kHz with CPU 224 XP with pulse-width modulation and pulse no-pulse setpoint – e.g. for controlling stepper motors

- 2 timed interrupts starting at 1 ms and adjustable in increments of 1 ms – for bumpless control of rapidly changing processes

- Fast analog inputs – signal conversion with 25 μs, 12-bit resolution

- Real-time clock

Timed interrupts

- Between 1 and 255 ms, with a resolution of 1 ms

- For example: it is possible to record and process signals on screw insertion machine at 3000 RPM after just a quarter turn. This enables very precise recording, for instance, of tightening torques to ensure optimum fastening of the screw.

Fast counters

- Operating independently of each other, of other operations and of the program cycle

- Interrupt triggering when user selectable counted values are reached – reactiontime from the detection of an input signal to switching of an output is 300 μs

- 4-edge evaluation when incremental position encoders are used for exact positioning

- Modular expandability

Alarm inputs

Siemens Simatic S7-200 Software

- 4 independent inputs

- For registering signals in rapid succession

- Response time of 200 μs–500 μs for signal detection/300 μs for signal output

- Response to positive-going and/or negative- going signal edge

- Max. 16 interrupts in one queue depending on prioritization